AMBRA

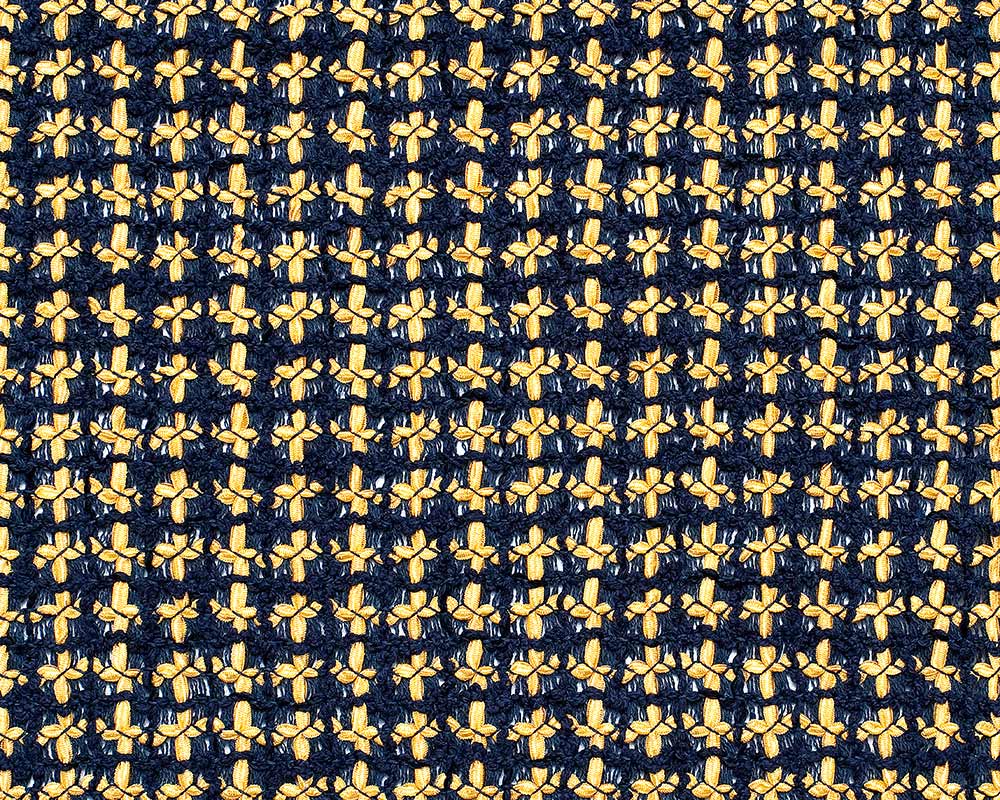

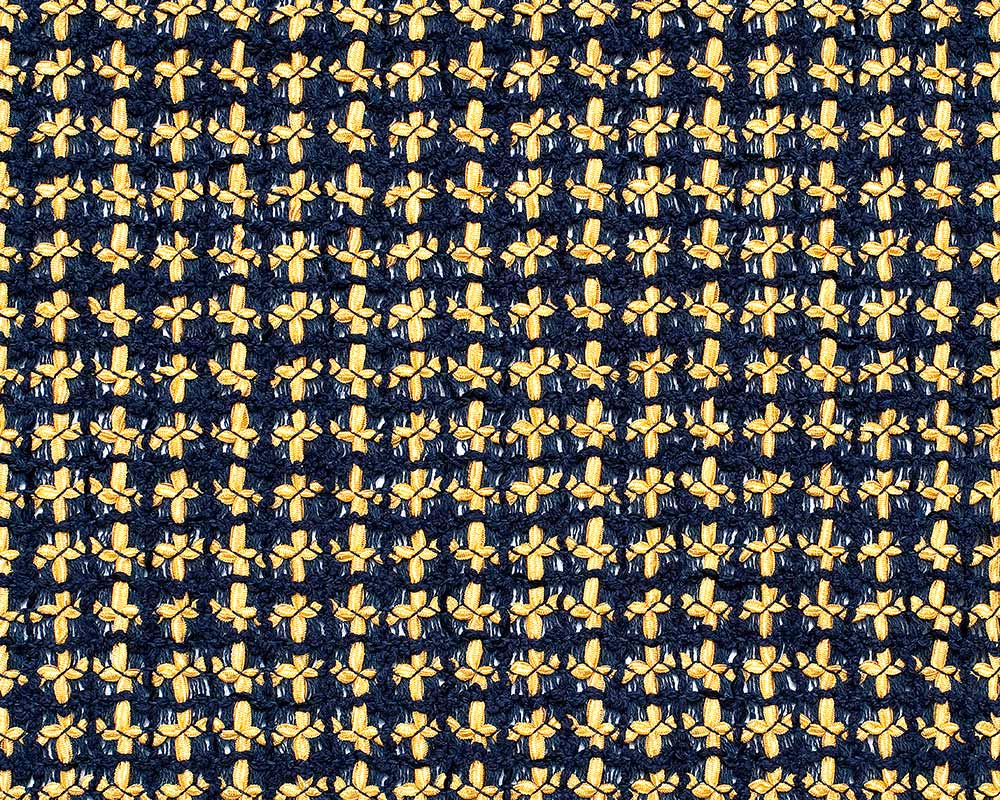

Fabrics

ELECTRONIC crochet knitting machine for the production of clothing fabrics (such as scarves and shawls) and technical textiles that COMETA offers as a great innovation thanks to the drive of electronical drive of the drawing bars. AMBRA uses both bearded needles and latch needles and can work with natural and synthetic yarns. Machine also available with compound needle, furthermore 2 or 4 weft bars can be electronically controlled in such a way as to have a warp and weft effect thus obtaining a fabric similar to traditional knitwear. The basic feature of AMBRA is the high speed of work in relation to the type of article to be produced and the type of yarn used thanks to a special kinematic of the needle bar carrier. AMBRA has a front control at 8,000 repetitions that allow the bars to perform the desired drawings. The patterns are loaded by means of the front keyboard or with USB/LAN key previously loaded with data by the PC program supplied with the machine. AMBRA on demand can be provided with a 2 piker kit, mobile cutting and product holding device, for the production of lateral fringes up to 150 mm. AMBRA also has an UPS that in case of black-out allows the possibility to not lose the position of the pattern avoiding reset when restarting the machine. AMBRA has a control system of all the anomalies that are shown on the display, stopping automatically the machine. The machine has a constant updating according to EC safety standards .

– 6/8 electronically driven weft bars

– Check panel for automatic stop of machine in case of breakage of weft and warp yarn, empty cones, improper winding of the product

– Machine stop lamp : blinking in case of anomalies, fixed in the case of stop

– Inverter – electronic speed variator

– Electronic system patented at 8000 repetitions on 6/8 weft bars

– Programming front screen

– Slow motion button

– Revolutions counter device

– Unit counter device with preselector

– Meters counter device with preselector

– 4 shifts meters counter device

– Electronic stitch density regulator device

– Weft yarns frame with 2 reeds

– Adjustable anti vibration feet

– General stop and safety machine device in accordance with EC standards.

– USB/LAN connection

DEVICES ON REQUEST:

Product collector with cardboard behind the machine

Foot platform

Positive warp yarn feeder (mechanical adjustment)

Positive warp yarn feeder (electronical adjustment)

1-2 bars weft device up to machine width 4 rollers yarns feeder adjustment with inverter

3 rollers feeder mechanical adjustment

3 rollers elastic yarns feeder mechanical adjustment

Kit for shifting up to 280 mm in 1,2,3 or 4 bars

2 bars weft device for shifting up to 300/600 mm (mechanical adjustment)

Piker device

Piker device -scissors

2 pikers device-scissors + product holding device

Mobile piker (single and double versions)

Bouclè device

Rods bars with and without supports (stroke 150 mm or 45 mm)

Weft compensation springs with support

Weft compensation springs

Argo thermofixing device

Argo additional thermofixing device

Electronic picking up device for knitting

ZEUS

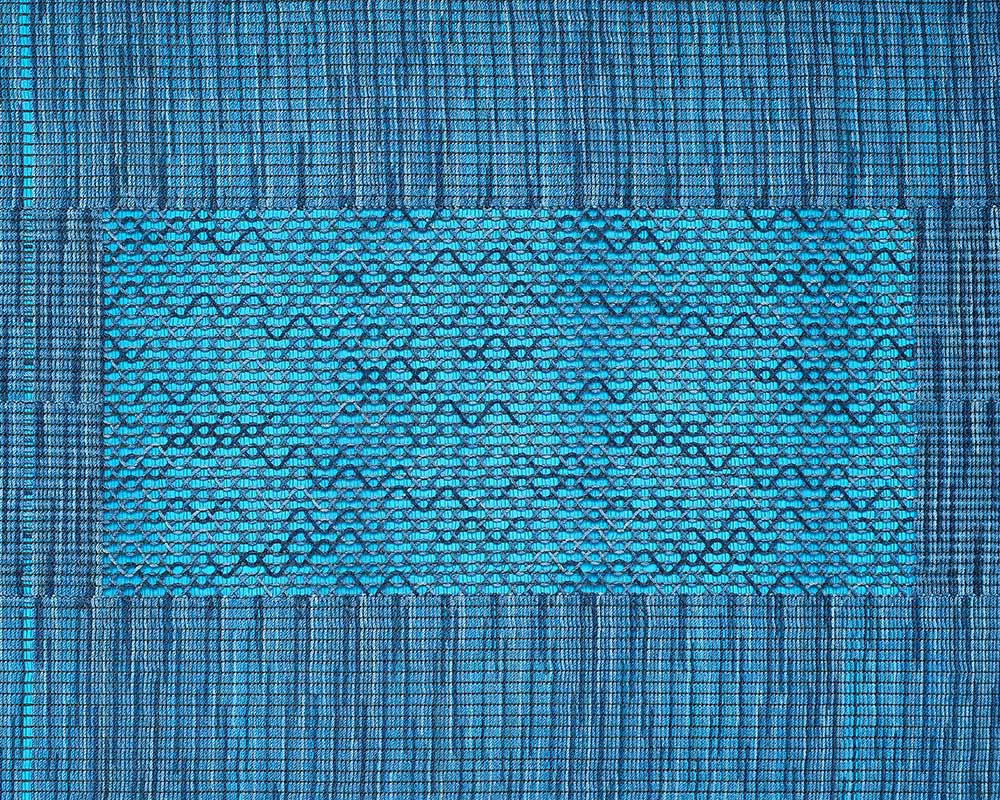

Fabrics

MECHANICAL crochet knitting machine for the production of clothing fabrics (such as scarves and shawls), bedspreads, decorative bands and technical textiles. ZEUS uses both bearded needles and latch needles and can work with natural and synthetic yarns. It is particularly suitable for the production of fabrics using a stroke up to 60 mm. The basic feature of ZEUS is the high speed of work in relation to the type of article to be produced and the type of yarn used, also thanks to the particular kinematic of the needle bar carrier. ZEUS is equipped with 8 weft bars driven by link chain as well as by a weft device to make shifting up to 100mm on 2 bars moved in alternative to the link chain. ZEUS can receive different devices on demand: box for the cutting device and for the electronic device for bar stop in order to make scarves with fringes of the desired lenght. ZEUS check panel for automatic stop of machine in case of breakage of weft and warp yarns,empty cones, improper winding of the product. Each of these anomalies is displayed on a display provided to the panel and the machine stops automatically. The panel includes a pick counter with preselector and, on demand, a meters counter with preselector; finally, the machine has a constant control of the EC safety standards.

– 8 mechanical weft bars

– Link chain extension

– Check panel for automatic stop of machine in case of breakage of weft and warp yarns, empty cones, improper winding of the product

– Machine stop lamp: blinking in case of anomalies, fixed in the case of stop

– Steel links

– Revolution counter

– Weft yarns frame with 2 reeds

– Adjustable anti vibration feet

– General stop and safety machine device in accordance with EC standards.

DEVICES ON REQUEST:

Additional simple collector for reel

Product collector with reel behind the

machine adjustment with clutch

Reel for collector

Product collector with cardboard behind the machine

Foot platform

Positive warp yarn feeder

2 bars weft device for shifting up to 300/600 mm (mechanical adjustment)

3 rollers elastic yarns feeder (mechanical adjustment)

4 rollers yarn feeder adjustment with inverter

Kit for shifting up to 120 mm in 1, 2, 3 or 4 bars

Piker device

Piker device -scissors

2 pikers device-scissors + product holding device

Mobile piker (single and double versions)

Bouclè device

Rods bars with and without supports (stroke 150 mm or 45 mm)

Meters counter

Compensation springs for weft yarns with supports

Compensation springs for weft yarns

Argo thermofixing device

Argo additional thermofixing device

Inverter – electronic speed variator

PRISMA

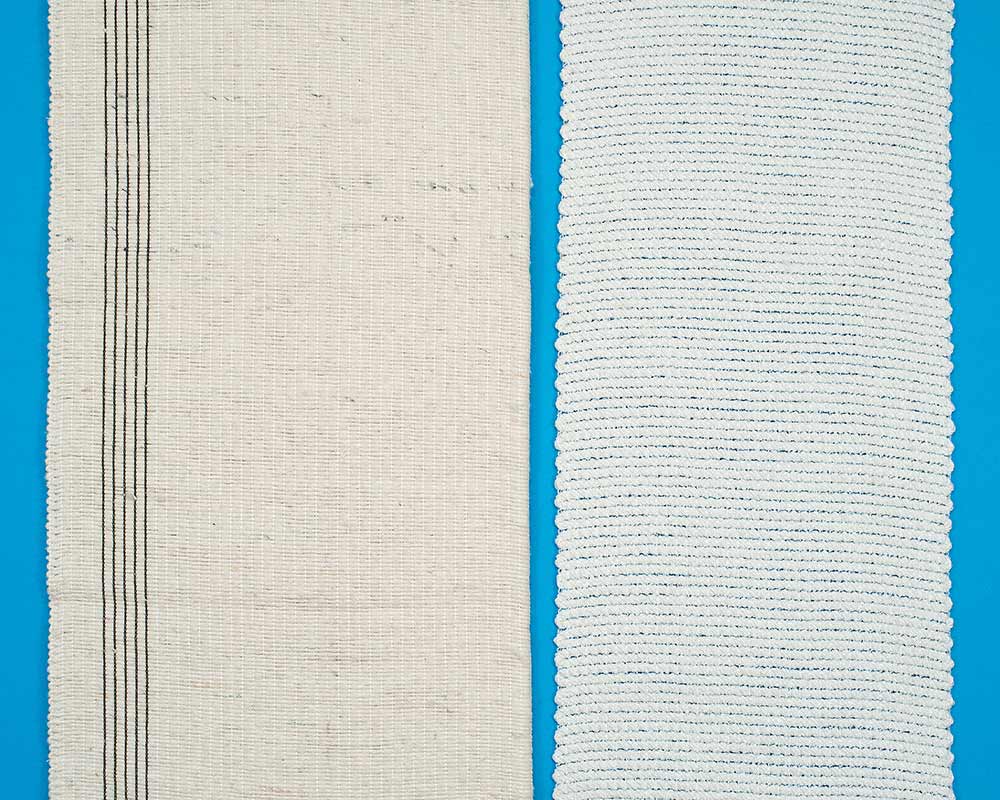

Fabrics

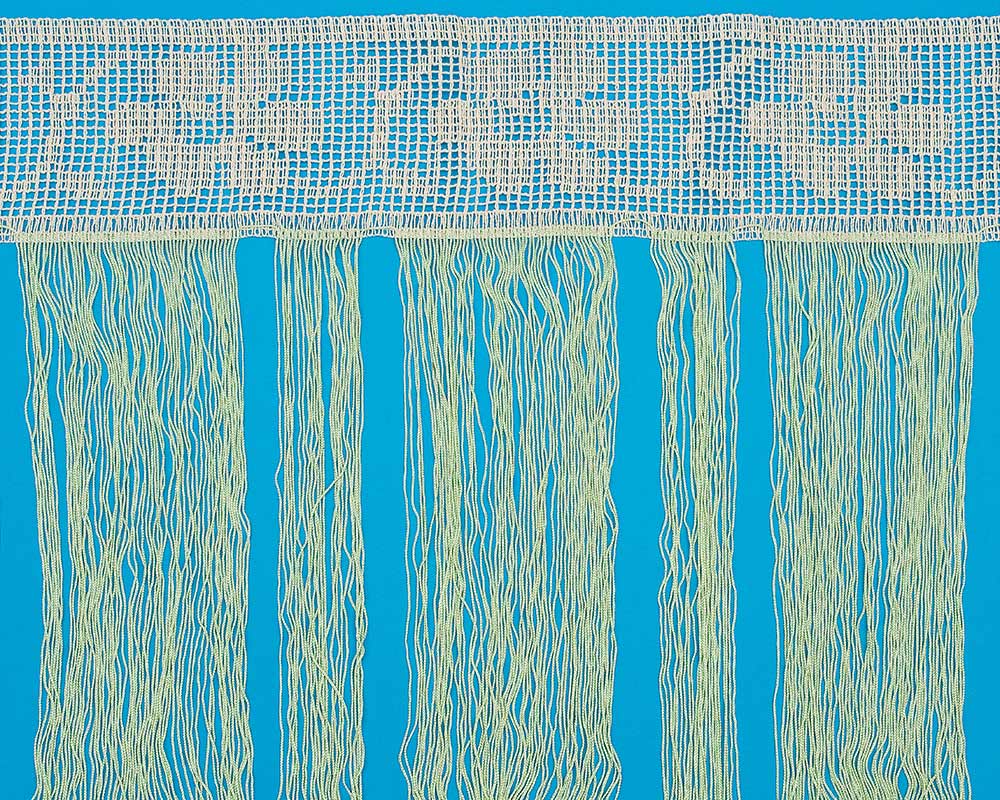

ELECTRONIC crochet knitting machine for the production of trimmings and fringes up to a maximum width as the whole needle bed. PRISMA uses bearded needles and latch needles. The special feature of PRISMA is the possibility to make shifting up to maximum needle bed width thanks to a new concept electronic weft device that allowed to harmonize the technology and the aesthetics of the machine. PRISMA is equipped with 1,2 or 3 weft bars electronically driven by a frontal control at 8,000 repetitions that can be used individually or for each bar. PRISMA thanks to the new electronic weft device allows shifting equal to the total machine width with intermediate stops, being able to create jagged fringes of considerable size. The programming of the weft device is made by a keyboard applied directly on the machine. PRISMA is also equipped with a “box” including: a cutting device, product holding device, 2 opposite piker bars. PRISMA has a check panel that controls all the anomalies that are shown on the display panel and the machine stop automatically. The machine has a constant updating accordingly to the EC safety standards.

PRISMA MACHINE IS SUPPLIED COMPLETE WITH:

– From 1 to 3 weft bars electronically driven

– Check panel for automatic stop of machine in case of breakage of weft and warp yarns, empty cones, improper winding of the product

– Machine stop lamp: blinking in case of anomalies, fixed in case of stop

– Inverter – electronic speed variator

– Patented electronic system with 8000 repetitions on weft bars

– Front screen for programming

– Slow motion button

– Revolution counter

– Unit counter with preselector

– Meters counter with preselector

– 4 shifts meters counter

– Weft yarns frame with two reeds

– 2 piker device and mobile product holding device

– Electronic stitch density regulator device

– Adjustable anti vibration feet

– General and safety machine stop device in accordance with EC standards.

– USB/LAN connection

DEVICES ON REQUEST:

Reel collector

Cardboard collector

Bench for reel or cardboard collector

From 1 to 6 weft bars stroke 150 mm.