GAIA

Trimmings

MECHANICAL crochet knitting machine for simple trimmings. GAIA uses bearded needles and latch needles and it can work with natural and sythetic yarns. It is suitable for the production of simple trimmings using a stroke up to 200 mm on 10 bars. With a particular kit it is possible to add 4 bars with stroke 300 mm. The main features of GAIA are the following: – high speed of the work according to kind of article to be produced and to the kind of yarns used, thanks also to the particular kinematic motion of the needle bar carrier. – use of the rods bars for a greater easy use of the utilizer of the frontal group of the bars. – execution of drawing by steel link chain GAIA is suitable for application of special “ mirror device”, known also under the name of «damina» or «tam-tam» and differential feeder device. All devices are mechanically driven with the maximum reliability that distinguishes the products COMETA. GAIA is also equipped with a “box” including the application for cutting device, mobile product holding device, 2 opposite piker bars. GAIA has a variable take down rollers system with hand wheel from 1 to 10 stitches per centimeter; this mechanical device makes a particular precision movement that moves the ratchet. A particular circular indicator allows to see with the utmost precision the increasing or decreasing of the stitch. GAIA on demand can be supplied a kit for milled weft bars. GAIA has a check panel that controls the breakage of weft and warp yarns, the improper winding of the product on stitch density regulator; all the anomalies are shown on the display panel and the machine stops automatically. The panel includes, on demand, a meters counter with preselector and the machine has a constant updating accordingly to the EC safety standards.

– 8/10 weft bars driven by link chain

– Check panel for automatic stop of machine in case of breakage of weft and warp yarns, empty cones, improper winding of the product

– Machine stop lamp: blinking in case of anomalies, fixed in case of stop

– Steel links

– Weft yarns frame with two reeds

– Pick counter with preselector

– Adjustable anti vibration feet

– General and safety machine stop device in accordance with EC standards

DEVICES ON DEMAND

Simple product collector

Lateral product collector from 1 to 4 rollers

Product collector with reel or cardboard

Reel for collector

Foot platform

Rack with and without brake (top)

Warp threads platform

4 rollers yarns feeder adjustment with inverter

Positive warp yarns feeder device

3 rollers elastic yarns feeder (mechanical adjustment)

Kit for shifting up to 150 mm with 1, 2, 3 or 4 bars

Special device for “Sea horse” effect

Mobile piker (single and double versions)

Weft compensation springs

Miller bars kit (stroke 50 mm)

Guide to swing weft tube closed to needle bed

Meters counter with preselector

Inverter – electronic speed variator

GIADA

Trimmings

ELECTRONIC crochet knitting machine for fringes, simple and elaborated trimmings that COMETA offers as innovation thanks to the bars electronically driven. GIADA uses bearded needles and latch needles and it can work with natural and sythetic yarns. It is suitable for the production of fringes, simple and elaborated trimmings using on 4 bars a stroke of 200 mm and on the other 4 bars a stroke of 300 mm for model 1008 (for model 1010 are used 6 bars with stroke up to 200 mm and the other 4 bars with stroke 300 mm). The main features of GIADA are the following: – high speed of the work according to kind of article to be produced and to the kind of yarns used, thanks also to the particular kinematic motion of the needle bar carrier. – use of the rods bars for a greater easy use of the utilizer of the frontal group of the bars. GIADA has a frontal electronic control with 8000 repetitions that allows weft bars to be electronically driven; repetitions can be used individually or for each bar. The patterns are loaded by means of the front keyboard or with USB key previously loaded with data by the PC program supplied with the machine. GIADA is suitable for application of special “ mirror device”, known also under the name of «damina» or «tam-tam» and differential feeder device available with single and double eight effect device. All devices are electronically driven as well as GIADA machine. GIADA is also equipped with a “box” including cutting device, mobile product holding device, 2 opposite piker bars. GIADA on demand can be supplied a kit for milled weft bars. GIADA has a check panel for controlling all the anomalies that are shown on the display panel and the machine stops automatically. The machine has a constant updating accordingly to the EC safety standards.

GIADA MACHINE IS SUPPLIED COMPLETE WITH:

– 8/10 weft bars electronically driven

– Check panel for automatic stop of machine in case of breakage of weft and warp yarns, empty cones, improper winding of the product

– Machine stop lamp: blinking in case of anomalies, fixed in case of stop

– Inverter – electronic speed variator

– Electronic system patented in 8000 repetitions

– Front screen for programming

– Slow motion button

– Revolution counter

– Unit counter with preselector

– Meters counter with preselector

– Electronic stitch density regulator device

– Weft yarns frame with two reeds

– Adjustable anti vibration feet

– General and safety machine stop device in accordance with EC standards.

DEVICES ON DEMAND

Simple product collector

Lateral product collector from 1 to 4 rollers

Foot platform

4 rollers yarns feeder adjustment with inverter

Positive warp yarns feeder device

3 rollers elastic yarns feeder (mechanical adjustment)

Special device for “Sea horse” effect

Mobile piker (single and double versions)

Weft compensation springs

Guide to swing weft tube closed to needle bed

Milled bars kit (stroke 150 mm or 50 mm)

Rack with and without brake (top)

Warp threads platform

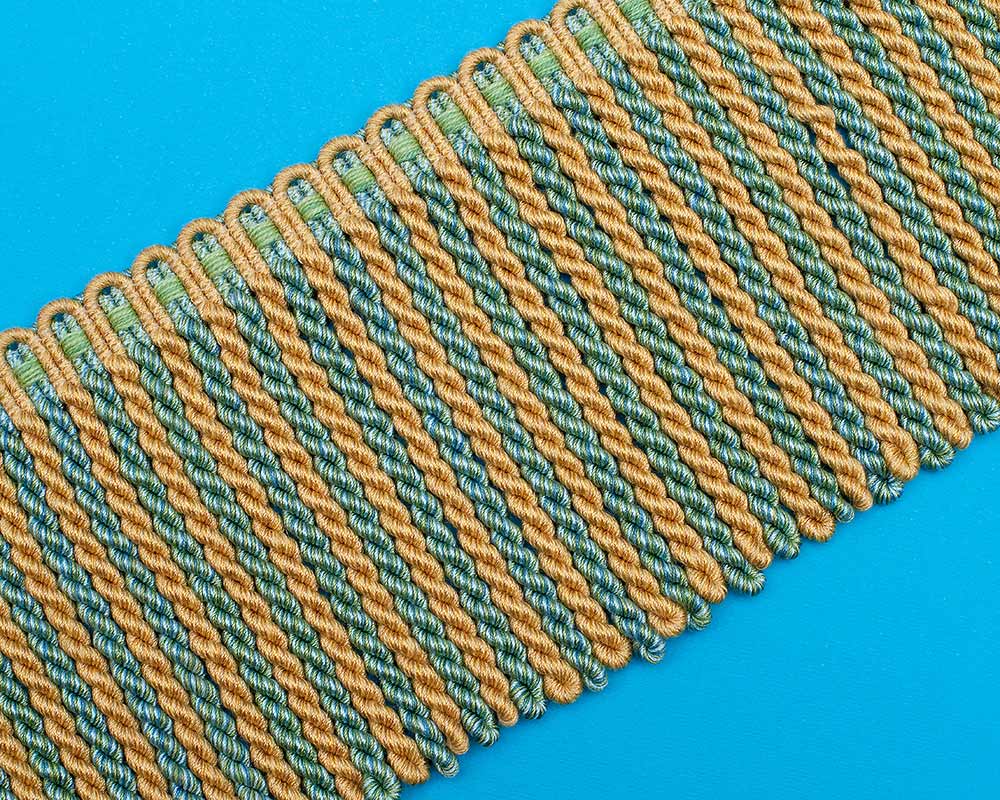

RIBES

Trimmings

ELECTRONIC crochet knitting machine for trimmings with twisted fringes of different sizes and pleasant effect that COMETA offers as innovation due to the bars electronically driven. RIBES uses both bearded and latch needles and it can work with both natural and synthetic yarns.It is suitable for the production of trimmings with fringes using a stroke up to 200 mm on 4 bars and 300 mm. on the other 4 bars. The main characteristics of RIBES are: – high work speed relating to the type of article to produce and yarn used, thanks to a particular kinematic of the needles bar carrier – use of the rods bars for a greater easy use of the utilizer of the frontal group of the bars RIBES has a frontal electronic control with 8000 repetitions that allows weft bars to be electronically driven; repetitions can be used individually or for each bar. The patterns are loaded by means of the front keyboard or with USB key previously loaded with data by the PC program supplied with the machine. RIBES is supplied with a box including mobile product holding device and piker yarns take off device. It is necessary, for a better production rate and product quality, to supply RIBES with compensation springs and feeder GIOVE or MINIGIOVE. RIBES is supplied with 4 rotating points groups for the production of twisted product complete with 4 roller sectors in drag. The groups are controlled by a check device that permits the automatic regulation of the torsion by regulation from the keyboard. The user can use some other groups accordingly to his requirement. RIBES has a control system of all the anomalies that are shown on the display, stopping automatically the machine. The machine has a constant updating according to EC safety standards

RIBES MACHINE IS SUPPLIED COMPLETE WITH:

– 8 weft bars electronically driven

– Check panel for automatic stop of machine in case of breakage of weft and warp yarns, empty cones, improper winding of the product

– Machine stop lamp: blinking in case of anomalies, fixed in case of stop

– 4 roller sectors for twisted fringes

– 4 points groups for twisted product

– Inverter – electronic speed variator

– Electronic system patented in 8000 repetitions on 8 weft bars

– Front screen for programming

– Slow motion button

– Revolution counter

– Unit counter with preselector

– Meters counter with preselector

– 4 shifts meters counter

– Electronic stitch density regulator device

– Weft yarns frame with two reeds

– Adjustable anti vibration feet

– General and safety machine stop device in accordance with EC standards.

DEVICES ON DEMAND

Simple product collector

Lateral product collector from 1 to 4 rollers

Product collector with reel or cardboard

Reel for collector

Foot platform

Rack with and without brake (top)

Warp threads platform

4 rollers yarns feeder adjustment with inverter (MINIGIOVE)

3 rollers elastic yarns feeder (mechanical adjustment)

Twisted cordon feeder device adjustment with inverter (GIOVE)

Tube movement guide for twisted product

Fringe twisting device

Weft compensation springs

Scissors